Pressure Sensors Installation Method / Differential pressure

Pressure sensor calibration by direct comparison using its displayed value. 1. Once it is properly set up and has stabilized, pump the necessary pressure. 2. Supply an increasing pressure. S imulate at least 5 setpoints covering the entire range. 3. Then apply pressure in decreasing order once the maximum pressure is reached.

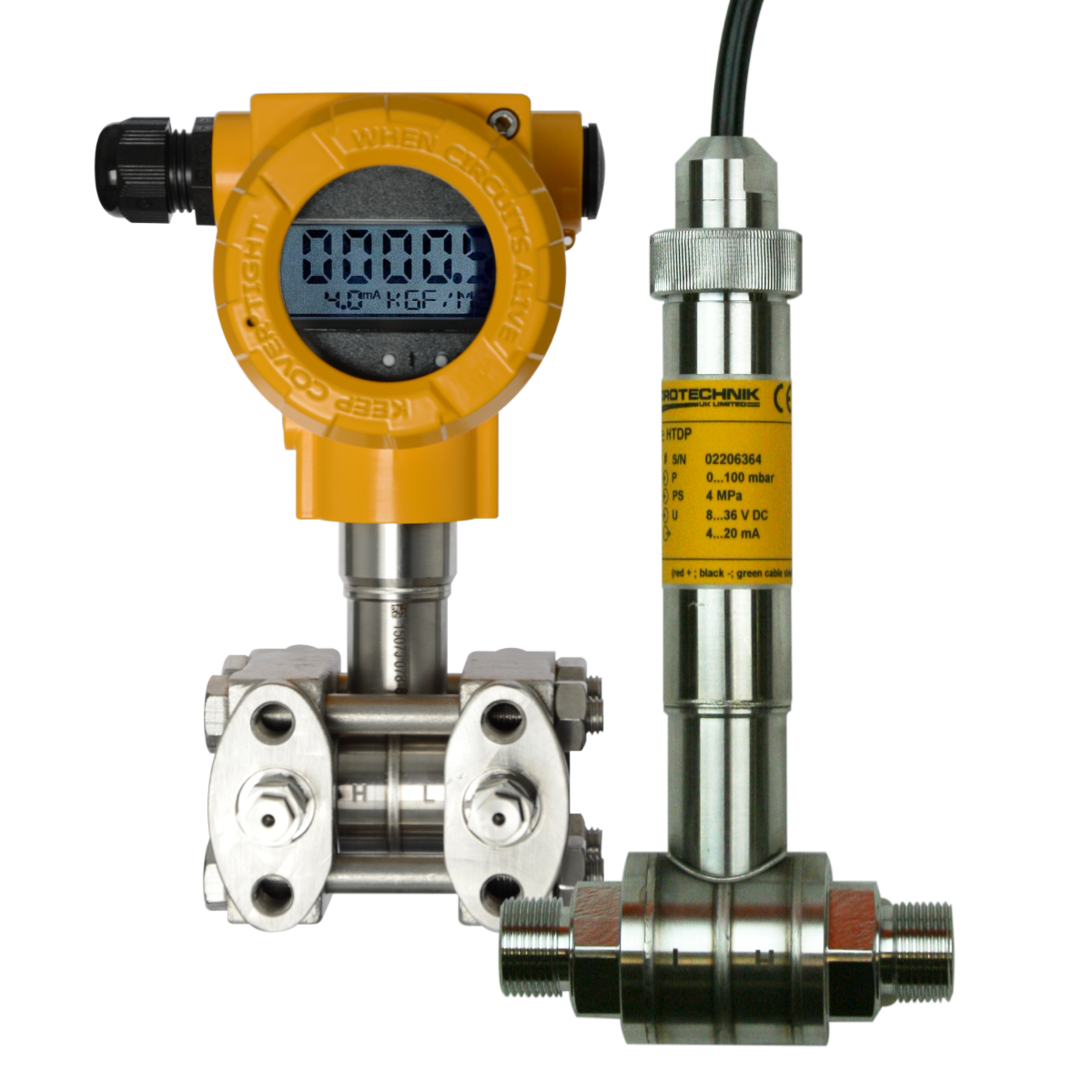

Differential pressure transducers and pressure transmitters

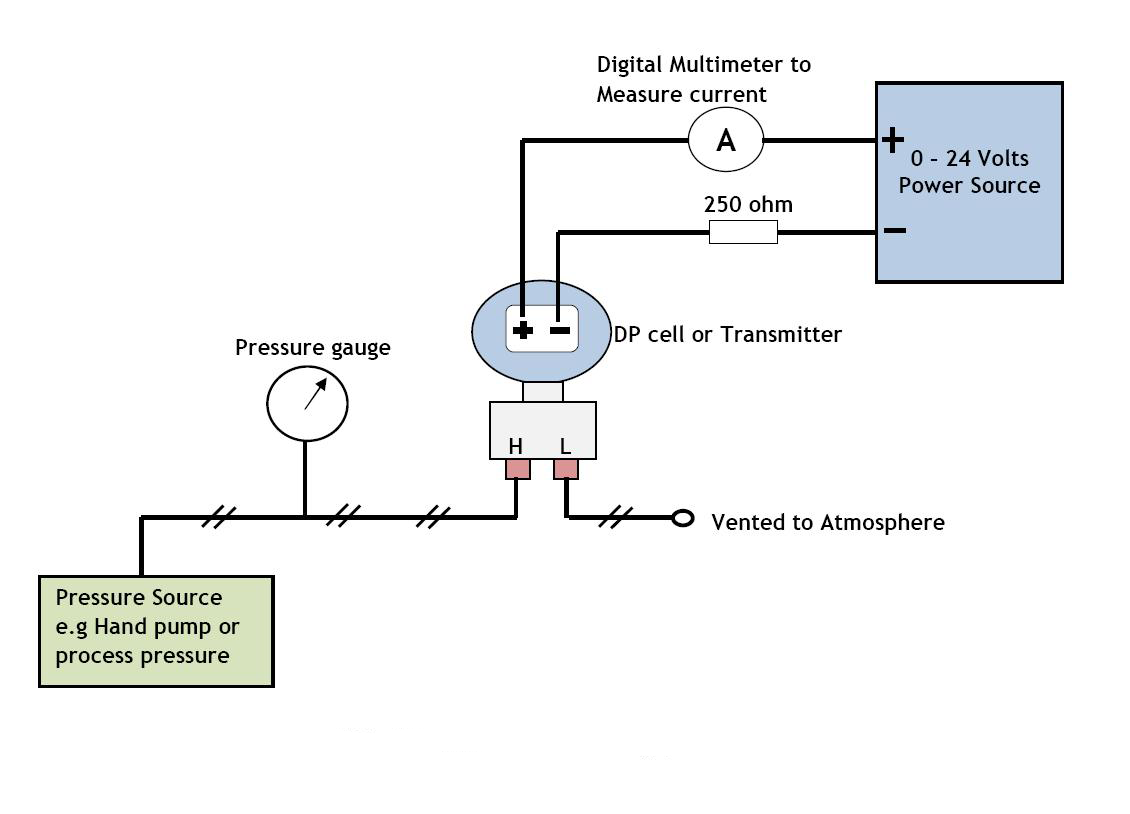

Differential pressure calibration involves adjusting and verifying the accuracy of pressure instruments that measure the difference in pressure between two points. This calibration process ensures that the instruments provide precise and reliable readings, allowing for accurate monitoring and control of various processes. Understanding.

DIFFERENTIAL PRESSURE TRANSMITTER CALIBRATION OF DIFFERENTIAL

A crucial factor is to align your standards and formulae to the devices when calibrating to get the most accurate output. Sensors tend to give offset values due to slightly higher or lower curves than the ideal linear output. This can be corrected with various calibration methods such as single point, two point, and multi-point.

How to Calibrate a Pressure Transmitter using HART Communicator YouTube

In most applications, the pressure sensor is considered the primary reference and is perhaps the only pressure measurement in the entire system. Therefore, one of the most important factors to consider when using any re-calibration method is that there must be a known Reference Pressure condition that can be applied to the sensor.

How to Calibrate and Adjust a Differential Pressure Switch Learning

Non-linearity is determined by the five-point calibration method. A pressure standard (a device know to be at least five times more accurate that the pressure sensor) is used to apply pressures at 0%, 50%, 100%, 50% and 0% of the sensor full scale.. For differential pressure sensors - those having a plus and minus full scale range, the.

How To Calibrate Differential Pressure Transmitter With Square Root

Differential pressure sensors are common in the process industry and cover a variety of applications. To understand what a differential pressure sensor is, it becomes important to put it in contrast to other pressure measurement types.. This is the least accurate method for calibration of DP sensors. Example 2 - Using an Low pressure.

MPS20N0040D Pressure Sensor Calibration with Arduino — Maker Portal

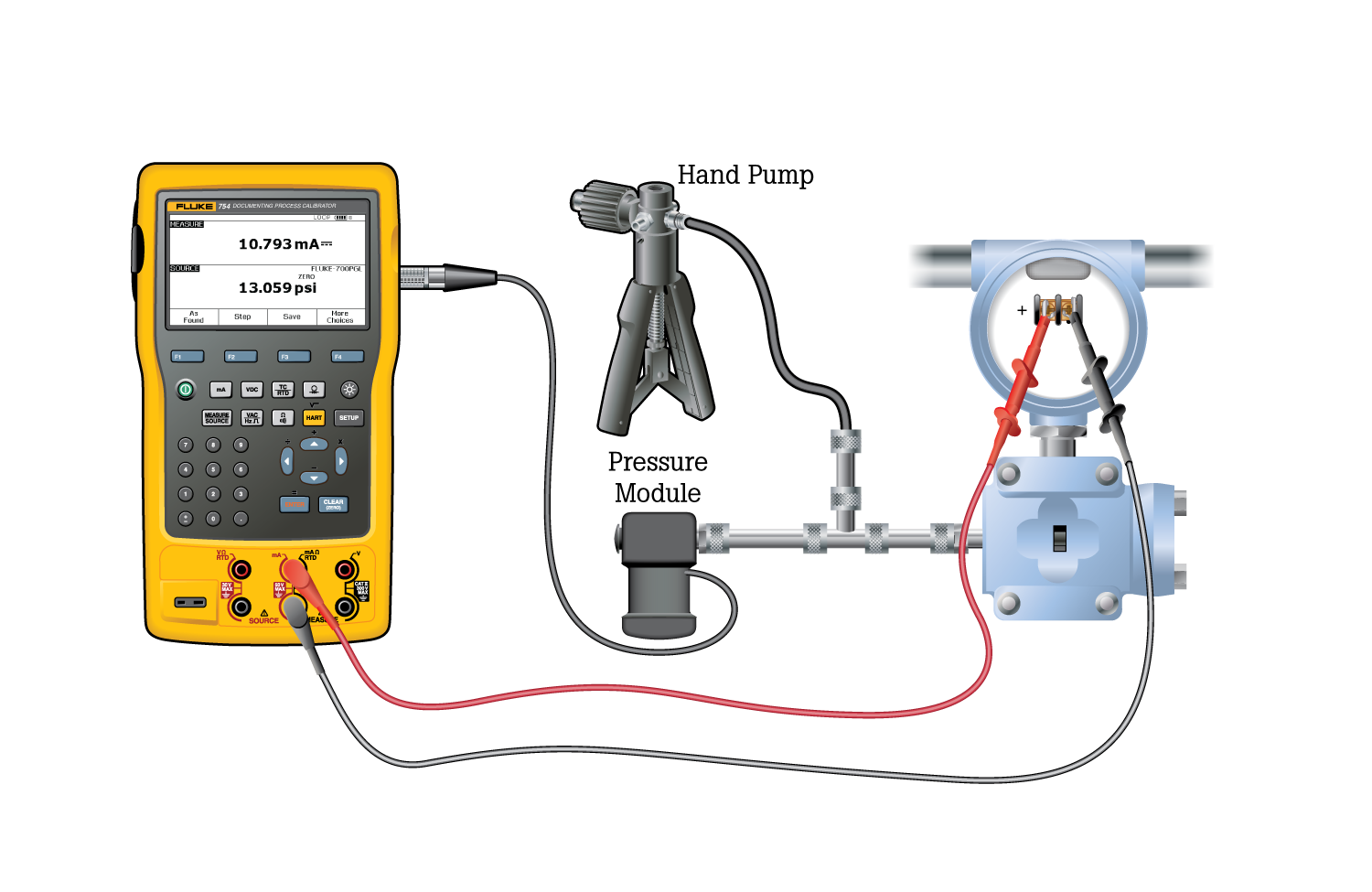

Switch on the pressure calibrator and open the vent by turning it counterclockwise. Press the zero button and then close the vent. Select PSI by clicking the Units button and press the zero button. Close the bleed valve and move the pressure vacuum values to "+". Create a pressure of 3 psi using the hand pump.

Calibrate the pressure sensor Rose Calibration Company; Quality

When a differential pressure is applied to the sensor, the diaphragm deflects away from one coil and towards the opposite coil.. pressure sensors with shorter response times are better for accurate measurements, but, when pressure changes are slow, a higher response time can be more adequate due to pressure sensors' lower cost and greater.

Typical Calibration Procedure of Differential Pressure Transmitter

Here's a simple procedure: Manual Zeroing: Manually adjusting the zero point is a conventional method, and its operation is straightforward. First, place the sensor in a no-pressure state and connect it to a measuring device. Then, adjust the sensor's output value to zero. When adjusting, refer to the sensor's user manual to ensure the.

Onsite Pressure Calibration Instrument Technologies Inc.

Piezoresistive pressure sensors exhibit inherent nonlinearity and sensitivity to ambient temperature, requiring multidimensional compensation to achieve accurate measurements. However, recent studies on software compensation mainly focused on developing advanced and intricate algorithms while neglecting the importance of calibration data and the limitation of computing resources.

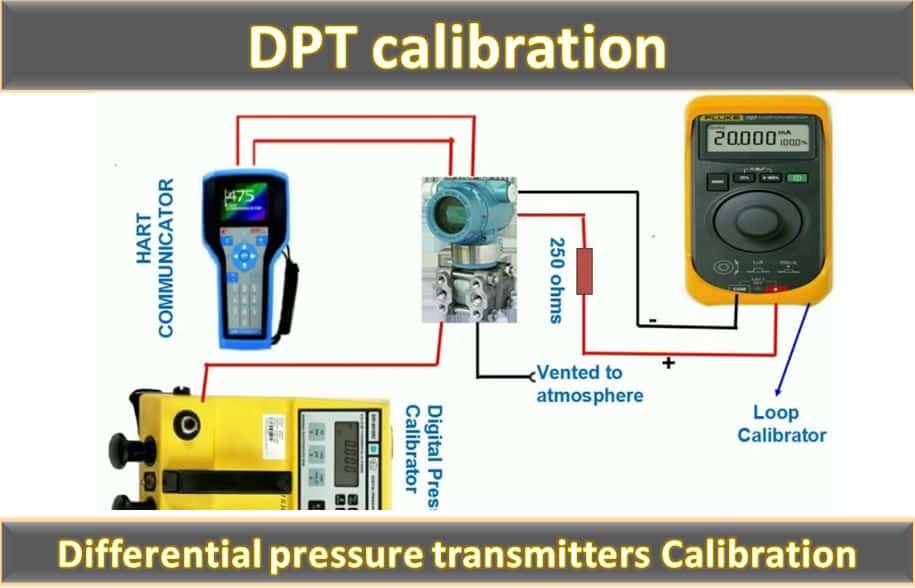

How to calibrate a Differential Pressure Transmitter (DPT)?

SPAN. Span is defined as the full scale output (FSO) voltage minus the offset voltage. For example, if at 15 psia an output of 101 mV was obtained and at 0 psia the offset voltage was 1 mV, the span would be 100 mV (101 mV (FSO) - 1 mV (offset) = 100 mV full scale span). It is important to note that for an absolute sensor, span is also.

Pressure Transmitter Calibration/Verification YouTube

Calibrating Differential Pressure Sensors Additel Corporation 22865 Savi Ranch Parkway, Ste F Yorba Linda, CA 92887 Introduction Differential pressure sensors are common in the process industry and cover a variety of applications. To understand what a. This is the least accurate method for calibration of DP

How to calibrate(Calibration) Differential pressure transmitter using

Hence, it is essential to adjust the effect of the static pressure as you calibrate the differential pressure sensor. Turn Down Ratio. Think of the range ratio as the difference between the highest and lowest values a differential pressure sensor can measure with acceptable precision.

Highly Accurate Low Differential Pressure Sensor IndustryAsia

Slightly open the LO side bleed valve to reduce LO side pressure (increase differential pressure) until the normal operating differential pressure appears on the differential pressure gauge. Close the bleed valve to stabilize differential pressure. Contacts should close (make) by the time normal operating differential pressure is reached.

Pressure Transmitter Calibration Procedure InstrumentationTools

Calibration Methods In the next few pages, we'll look at three different types of calibration: One Point Calibration Two Point Calibration Multi-Point Curve Fitting One Point Calibration One point calibration is the simplest type of calibration. If your sensor output is already scaled to useful measurement units, a one point calibration can be.

Differential pressure transmitters Calibration DPT calibration

The steps below outline a systematic approach to calibrating a differential pressure transmitter. 1. Gathering Essential Tools and Equipment. Before you start the calibration process, it's essential to gather the necessary tools and equipment. These include a pressure source, a digital multimeter, a calibration hand pump, tubing, and a computer.

- Camarero De Pisos En Barcelona Sin Experiencia

- Hotel Tropic Relax Benidorm Opiniones

- Wifi Ac 600m Wireless Usb Adapter Driver

- Elias Torres Martinez Lapeña Arquitectos

- Como Instalar Bases De Piedra Para Pilares De Madera

- Literatura Dramática Y Teatro Universidades

- Funciones En Hoja De Calculo De Google

- Libro Blanco De La Nutricion Infantil

- Fincas Para Bodas Tenerife Sur

- Soñar Con Ropa Nueva Y Zapatos Nuevos